Last winter I was asked by a friend to get a couple of these kits for him, and when I did, I got the Stirling Engine kit for myself as well. I've long been fascinated by this kind of heat engine, and I'm a sucker for good working models like this. The model is well designed and put together, with aluminium bottom and top plates and a solid framework. There's plenty of thoughtful small details here, like the fact that the top aluminium plate has not only raised outside edges, but the holes for the center axis and the membrane "cylinder" have raised edges as well. An easy way to increase the engine power is to put cold water or ice cubes on the top and this prevents any melt-water from dribbling into the main cylinder (I'll get to what all these things actually do below).

To the left, the displacer (a disc of foam rubber) and its thin axis, and the displacement cylinder seen from below. The axis of the displacer goes through the center of the top plate. The white round thing is a rubber membrane that acts as the power piston, bulging up and out when pressure is high, and in when it is low.

The center and right pictures show the engine assembled. The power piston is again the white circle, and it is connected to the big vertical disc flywheel. The displacer is connected to the same flywheel on the other side.

The engine in operation. There's hot water in the jam jar (a childhood favourite, that jar) driving the engine. Air heats up at the bottom plate over the hot water, and cools at the top. If we put a couple of ice cubes on top we'd make it run even faster.

Stirling Engine Operation

So, how does it work? A Stirling engine is a heat engine. Like many other engines, it uses the fact that pressure and temperature really is the same thing; an increase in temperature is an increase in pressure, and an increase in pressure is an increase in temperature (that's why your bicycle pump becomes warm when you use it). When you heat up a gas, the pressure increases, and when you cool it, it decreases.

A gasoline engine burns a bit of gasoline to quickly generate lots and lots of hot gas in a cylinder, hot, high-pressure gas that pushes down on the piston in the cylinder and moves the engine. The gas is expelled when the piston is pushed to the bottom, and the cycle restarts once the piston is back at the top. A steam engine is similar, except it creates the hot gas (steam) outside of the cylinder, not inside, so it needs a separate boiler for the heat/pressure generation.

A Stirling engine is different. It uses a temperature difference in space - a cold area in one place and a hot area in another - to generate movement. It does not need to periodically burn anything, like a gasoline engine, and it does not need to create and release hot gas like a steam engine. It reuses the same gas, periodically heating and cooling it. And it doesn't need any "hot" heat, all it needs is a temperature difference.

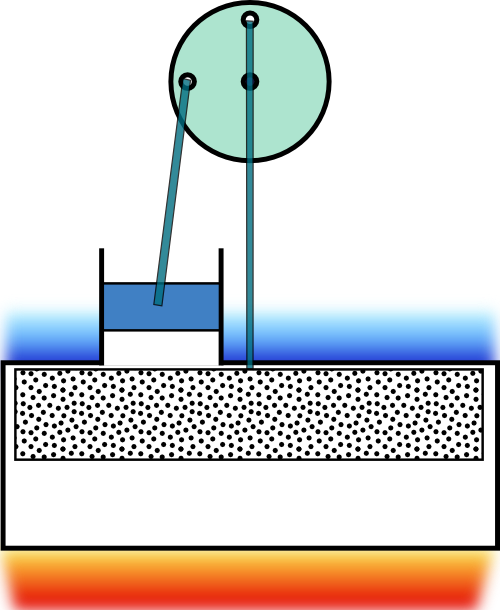

Take a look at the illustration on the left. We have a cylinder with a heat source at the bottom and cooling at the top. The cylinder is totally enclosed. Inside the cylinder we have air, and we have a loose block - a displacer - of some kind (the green rectangle). Note that the displacer is not a snug fit in the cylinder; air can move around it. But it does prevent most air from being in the same end of the cylinder as itself - it displaces the air. At left, in (a), the displacer is at the bottom, so most of the air is at the top. The top is cold, so the air cools down as well (the blue '-' symbols), and so the pressure drops in the cylinder (cool means low pressure, remember). If we move the displacer up to the top, as in (b), the air have to move down, out of the way, into the heated part of the cylinder. The air heats up (red '+' symbols) and so the pressure increases.

Take a look at the illustration on the left. We have a cylinder with a heat source at the bottom and cooling at the top. The cylinder is totally enclosed. Inside the cylinder we have air, and we have a loose block - a displacer - of some kind (the green rectangle). Note that the displacer is not a snug fit in the cylinder; air can move around it. But it does prevent most air from being in the same end of the cylinder as itself - it displaces the air. At left, in (a), the displacer is at the bottom, so most of the air is at the top. The top is cold, so the air cools down as well (the blue '-' symbols), and so the pressure drops in the cylinder (cool means low pressure, remember). If we move the displacer up to the top, as in (b), the air have to move down, out of the way, into the heated part of the cylinder. The air heats up (red '+' symbols) and so the pressure increases.Now, how do we make use of this? If we could make that displacer move up and down periodically, we would make the pressure increase and decrease along with it. And if we have pressure that changes, we could have a piston be moved by the pressure (like in a steam or gasoline engine) and run the motor. So, what we do is, we add a piston to the top, and connect it to a crank (the mechanical kind, not a person). When the piston moves up and down, it pushes the crank, which will

This really is the same cylinder as in the first illustration, we just made the whole cylinder wider to match the real Stirling engine model. As before we have a big, flat block to displace the air in the wide cylinder. At the top, on the left side, we have attached a small "extra" cylinder with a piston (unlike the big block, this piston is air-tight). If the air pressure in the big cylinder is high, the piston is pushed upwards and out. If the pressure is low - lower than the outside air - it will actually be pushed down and in from the outside. If you look at the pictures of the real engine at the top, we don't have a cylinder and piston at the top, but a soft rubber membrane that will bulge outwards or inwards instead.

The small cylinder is connected to the wheel at the top with a rod. As the cylinder moves up and down, the rod will push and pull the wheel, making it rotate. The rotating wheel, in turn, will push and pull a second rod that moves the big block up and down in the big cylinder. And as we saw before, the block moves the air from the hot end to the cold and back again, generating alternating high and low pressure.

Work cycle of a Stirling engine. 1) the air at the bottom heats up, creating pressure on the small power piston, which moves up and rotates the flywheel. 2) This moves the big displacer down, shuffling the air upwards, 3) cooling down at the top, which reduces the pressure and allows the power piston to move down. 4) This drags the displacer upwards and moves the air down to the bottom to be heated again, completing the cycle.

In other words: as the air moves up and down in the cylinder, its temperature, and thus its pressure changes, moving the small piston up and down. The piston in turns rotates the wheel, which in turn moves the big block up and down, causing the air to move in the big cylinder, which changes its temperature...

As long as there is a steady temperature difference between the two sides of the cylinder, the engine will keep running. And the difference does not need to be large; an efficient Stirling engine can run on a difference as small as 7°C - it can run on the heat from the palm of your hand on a cool day. Theoretically, the Stirling engine is as efficient as a heat engine can be; in practice, though, there are lots of conflicting design issues that prevents it from achieving that. For instance, ideally, the air displacer block should have almost no clearance so that it really moves all air back and forth, but with no clearance between the block and the cylinder, the air resistance will make it difficult to move the air without using a lot of energy. There are several other similar contradictory constraints. That said, it can still be made quite efficient in practice as well.

So, what are Stirling engines good for?

Not cars or motorcycles, or airplanes or anywhere you need an engine that is both small and light as well as powerful. While the engine is efficient, it does become larger than the same-power gasoline or diesel engine. For a high-power engine you need a very large heat differential so parts need to be bulky and heat-tolerant, and you may need big cooling fins or a liquid cooling system for a large engine. Also, unlike a gasoline engine it needs a warm-up period, and you can't regulate the speed and power from moment to moment the way you can a gasoline or diesel engine. In this respect the Stirling engine is more like a gas turbine. Of course, if weight, power and quick regulation is really important to you, an electric motor beats all of these.

The steady speed and power means that the Stirling engine is good for power generation, especially if you can use waste heat from some other process to drive the engine. For a generator, the size and weight doesn't matter much. The engine is a pretty simple, robust design with few moving parts so it is reliable and easy to maintain - you can have it mothballed for a long time and still expect it to work when you start it. And as the heating is external, it can run on whatever heat source or fuel you happen to have available, including some (like contaminated diesel oil) that would gunk up and ruin an internal combustion engine. So they're an especially good choice for emergency generators or secondary power generators.

The engine is very quiet, does not vibrate, and does not need traditional fuel-air combustion as a heat source, so it is used in Swedish submarines as a secondary energy source; submarines using this technology has been sold to several countries, and the system has been licensed by Japan for use in their new submarines.

Another cool thing: The Stirling engine is reversible. Instead of using a temperature difference to generate motion, you can rotate the engine to generate a temperature difference. Remember, heat is pressure - as you rotate the axle, the air will be pressured (heated) by the small piston when it is in one end of the big cylinder, and de-pressured (cooled) when it is in the other. The faster you rotate, the greater the pressure difference, and the colder - and hotter - it gets.

If you are a home owner and this sounds like a heat pump, you're exactly right: an electric motor runs the pump (the Stirling engine), which in turn pumps heat from the outside air or from the ground beneath the house, heating the inside. This is three or four times as efficient as just using the electricity to heat a house directly.

This can also be used for refrigeration; while it's not used for household refrigerators (the normal vaporizing method is more efficient for small amounts of cooling), this "reverse Stirling" design is sometimes used when you want to make something really cold, like in a laboratory or a chemical factory, to create liquid oxygen or nitrogen for example.

The Stirling engine is just plain cool technology. I keep wanting to build and use a real one for something, it doesn't even matter what.

Herr Morén -

ReplyDeleteYes the Stirlings are pretty amazing engines. I love the way they can be used for supercooling.

One question, though--my understanding is that the fit must be very precise for the engine to function properly. Are the pistons of the play version machined?

No, the fit is mostly not critical at all. The displacer is of course entirely loose within the main cylinder; if it actually did fit precisely the engine would no longer work.

ReplyDeleteThe power piston needs to be a good fit, just like the pistons in an internal combustion engine or a steam engine. It'll still work with the piston leaking but you'll lose a bit of power. On this kit that problem is avoided altogether by using a rubber membrane as a piston, and that one is of course completely sealed.

The main cylinder top and bottom plates are fitted with O-rings so they're well sealed. The only leak is where the displacer shaft enters the main cylinder at the top. That is a thin metal tube with very little clearance, though so the leaking is minimal (I put a little bit of silicone grease on the shaft as well, reducing it further).

You could design the engine to be completely sealed. Over time I think you would want the air pressure to equalize in the main cylinder, though, so you're not working against an exterior air pressure differential. If you're using air as the medium, a small amount of leakage is an easy way of achieving that. Think of the leakage as a low-pass filter: as long as the air movement is negligible over the short course of one engine cycle it won't affect engine efficiency in any material way.

Ah yes, all the cool people like Stirling engines. I'm not surprised. :-)

ReplyDeleteSorry about the late comment, but you mentioned power generation, how electric motors beat the competition in vehicles, and use in Swedish submarines — so I thought you might be interested in this: a Swedish company testing a prototype hybrid electric car (link in Swedish), running off a Stirling engine powered by wood pellets. Ok, it's really a "test platform" rather than an intended product, but still. (There are links to some coverage in English at the company site too.)

It looks pretty neat — and the fuel is renewable and carbon neutral, widely available and even cheap. (essentially a byproduct, it's made from sawdust, if I understand things correctly)

Probably not the way to go for everyone, but it's an interesting mix of new (hybrid vehicles) and old (trees and the forest industry).

For a commercial Sterling engine check out: http://www.whispergen.com/main/HOME/

ReplyDeleteCheers!

Denis O'Callahan

There are a good number of commercial Stirling engines for sale today already, and many more if you count engines running "backwards" and designed as heat pumps, like the one you link to. Not new in other words, but then, all company need to push their products any way they can I guess.

ReplyDeleteGreat writeup!

ReplyDeleteSee my write up, and a video of my model stirling engine from Kontax running here:

http://rodgerswriting.blogspot.com/2009/06/my-model-stirling-engine.html